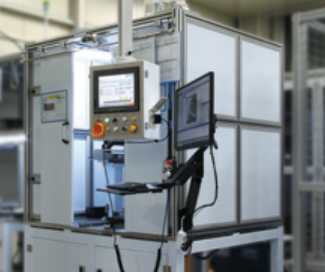

●Coil position alignment possible

after inserting

●Automatic sorting by multi axis robot arm

●Flexibility of coil positioning

●Coil alignment height can be

measured and corrected

●Coil spacing adjustment for secure

insulation performance

●Automatic operation using servo system

●Diameter and coil position correction

possible

●Causes No damage to coil insulation

●MAX 10 LAYER can be applied

●Configuration of parameter possible

for each layer

SPEED / ANGLE / HEIGHT

●Causes No damage to slot insulator

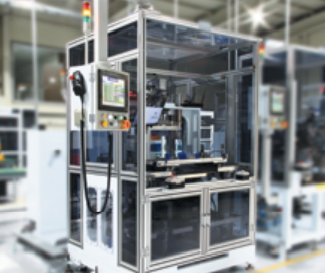

●Automatic welding inspection using

A.I vision

●Process optimization through CNN

algorithm

application

●Securing welding quality through

application of

protective gas

●SPATTER emergency setting

function possible

●Auto Positioning of Welding positioning

possible

by A.I vision

●Process optimization through CNN

algorithm application

●Quality pass/fail judgment possible

before/after

welding

●Automation of impregnation and coating

drying process

●Reduction of preheating/drying process

time using high

frequency oven

●Automatic operation by 6-axis ROBOT

●Temperature control function for

application of

impregnating liquid

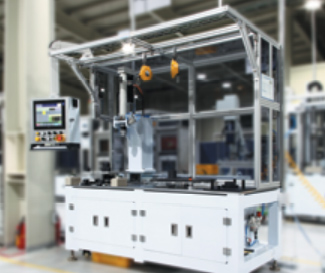

●Automatic stator assembly

●Stator press-in load and distance

management

●Fixed bolt tightening torque and angle

management

control possible

●Conveyor system applied

●Rotor automatic assembly

●Securing total assembly quality through a

utomation

application

●Rotor press fit distance and load

management

●Sealant application functiond

●Conveyor system applied